The Mechanical Marvels: Exploring the Wonders of Engineering

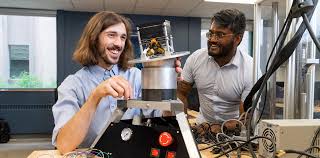

The Fascinating World of Mechanical Engineering

Mechanical engineering is a diverse and dynamic field that plays a crucial role in shaping the world we live in. From designing cutting-edge machinery to developing innovative technologies, mechanical engineers are at the forefront of innovation and progress.

One of the key aspects of mechanical engineering is the application of principles from physics, mathematics, and material science to create solutions that address real-world problems. Whether it’s designing efficient engines for cars, developing sustainable energy systems, or improving manufacturing processes, mechanical engineers are constantly pushing the boundaries of what is possible.

One of the most exciting aspects of mechanical engineering is its interdisciplinary nature. Mechanical engineers often collaborate with experts from other fields such as electrical engineering, computer science, and biology to create groundbreaking technologies that have a lasting impact on society.

From robotics to aerospace, from automotive to renewable energy, mechanical engineering offers a wide range of career opportunities for those with a passion for innovation and problem-solving. As technology continues to advance at a rapid pace, the demand for skilled mechanical engineers will only continue to grow.

In conclusion, mechanical engineering is a fascinating and rewarding field that offers endless possibilities for those willing to explore its challenges and opportunities. Whether you’re interested in designing the next generation of transportation systems or developing sustainable solutions for environmental challenges, mechanical engineering has something for everyone.

8 Essential Mechanical Maintenance Tips for Optimal Equipment Performance

- Regularly lubricate moving parts to prevent wear and tear.

- Keep tools and equipment clean and well-maintained for optimal performance.

- Follow manufacturer’s guidelines for maintenance schedules and procedures.

- Inspect machinery regularly for signs of damage or malfunction.

- Ensure proper training for operators to prevent misuse of equipment.

- Use appropriate safety gear when working with mechanical tools or machinery.

- Store tools in a dry place to prevent rusting or corrosion.

- Seek professional help for complex repairs or maintenance tasks.

Regularly lubricate moving parts to prevent wear and tear.

Regularly lubricating moving parts is essential in maintaining the efficiency and longevity of mechanical systems. By applying lubricants to components such as gears, bearings, and joints, friction is reduced, preventing unnecessary wear and tear. This simple yet crucial maintenance tip not only ensures smooth operation but also helps to prevent costly repairs or replacements down the line. Proper lubrication not only extends the lifespan of machinery but also contributes to overall performance and reliability, making it a fundamental practice in mechanical maintenance routines.

Keep tools and equipment clean and well-maintained for optimal performance.

It is essential to keep tools and equipment clean and well-maintained to ensure optimal performance in mechanical tasks. Regular cleaning and maintenance not only extend the lifespan of the tools but also enhance their efficiency and accuracy. By taking care of tools properly, mechanical professionals can prevent malfunctions, reduce downtime, and improve overall productivity. A clean and well-maintained tool is a reliable tool that can consistently deliver high-quality results, making it an indispensable asset in any mechanical work environment.

Follow manufacturer’s guidelines for maintenance schedules and procedures.

Following the manufacturer’s guidelines for maintenance schedules and procedures is crucial in ensuring the optimal performance and longevity of mechanical equipment. By adhering to these guidelines, you can prevent potential breakdowns, identify issues early on, and maintain the efficiency of your machinery. Regular maintenance not only extends the lifespan of the equipment but also helps in avoiding costly repairs down the line. Manufacturers provide these guidelines based on their expertise and knowledge of their products, so it is essential to follow them diligently to keep your mechanical systems running smoothly.

Inspect machinery regularly for signs of damage or malfunction.

Regular inspection of machinery is essential to ensure smooth operation and prevent potential breakdowns. By carefully examining equipment for any signs of damage or malfunction, mechanical issues can be identified early on and addressed promptly. This proactive approach not only helps maintain the efficiency and reliability of machinery but also minimises the risk of costly repairs or unexpected downtime. Inspecting machinery regularly is a simple yet crucial practice that can significantly extend the lifespan and performance of equipment in various industries.

Ensure proper training for operators to prevent misuse of equipment.

Ensuring proper training for operators is essential in the field of mechanical engineering to prevent the misuse of equipment. Well-trained operators not only understand how to operate machinery efficiently but also know how to maintain it properly, increasing its lifespan and performance. By providing comprehensive training, companies can minimise the risk of accidents, reduce downtime due to equipment failures, and improve overall productivity. Properly trained operators are better equipped to identify potential issues early on and take appropriate action, ultimately contributing to a safer and more efficient working environment.

Use appropriate safety gear when working with mechanical tools or machinery.

It is crucial to always use the appropriate safety gear when working with mechanical tools or machinery. Safety equipment such as goggles, gloves, helmets, and ear protection can help prevent accidents and protect against potential hazards in the workplace. By prioritizing safety measures and wearing the necessary protective gear, individuals can significantly reduce the risk of injuries and ensure a safe working environment for themselves and those around them.

Store tools in a dry place to prevent rusting or corrosion.

It is essential to store tools in a dry place to prevent rusting or corrosion. Moisture can quickly degrade the quality of tools, leading to inefficiency and potential safety hazards. By keeping tools in a dry environment, such as a toolbox or storage cabinet, you can prolong their lifespan and ensure they remain in optimal condition for future use. Regular maintenance and proper storage practices are key to preserving the integrity of mechanical tools and equipment.

Seek professional help for complex repairs or maintenance tasks.

When it comes to complex repairs or maintenance tasks in the realm of mechanical engineering, seeking professional help is paramount. Professionals possess the expertise, experience, and specialised knowledge required to tackle intricate challenges effectively and efficiently. By entrusting complex projects to skilled professionals, you can ensure that the job is done correctly and safely, avoiding potential pitfalls or costly mistakes. Professional assistance not only guarantees high-quality results but also provides peace of mind knowing that your mechanical systems are in capable hands.